+84 28 6 2792676

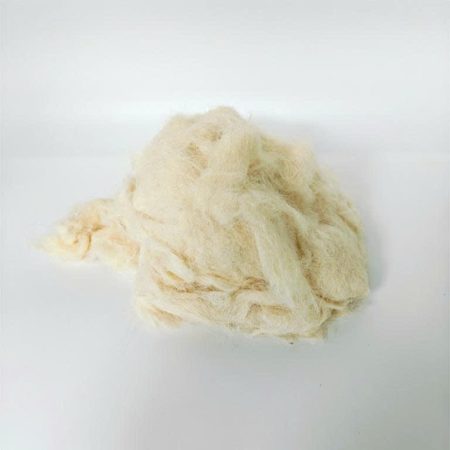

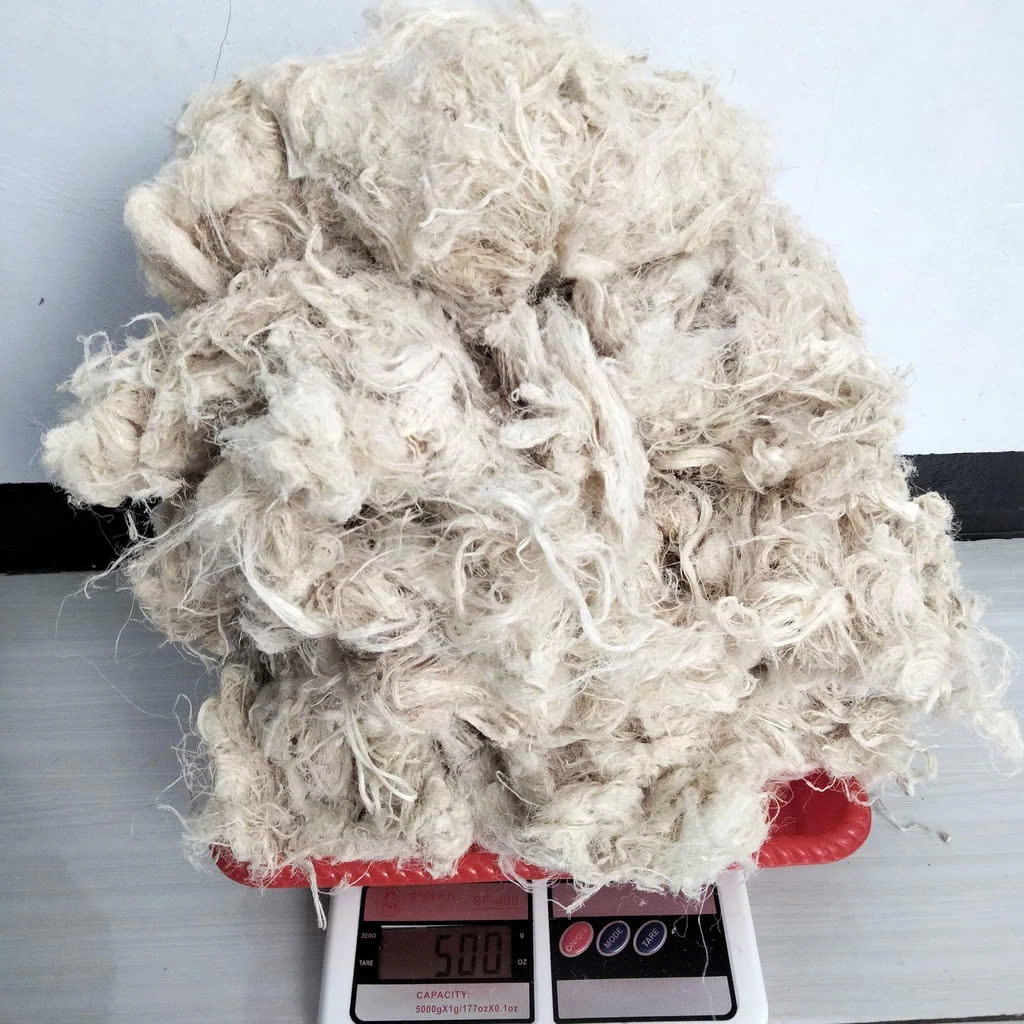

Handmade Natural pineapple Fibres/ Pineapple leaf fiber

- The pineapple fiber is soft, translucent, white or ivory in color and has luster.

- It has an elegant appearance similar to linen and is lightweight and easy to care for.

- Pineapple silk is considered the queen of Philippine fabrics.

- It is durable and resistant to moisture.

- The yield of fiber is 2.5 to 3.3% of the weight of green leaves.

- It can blend efficiently with any other fabrics.

- It can be washed and doesn’t need to be dry cleaned.

- An embroidered Pina garment is called as Pina calado.

- When the pineapple fiber is woven with silk it is called Pina Seda or Pina silk.

- A blend of abaca or silk is known as Pina jusi.

- It is 10 times coarser than cotton and the fiber and has a higher dye absorption tendency due to its higher moisture regain.

- It can be dyed with direct, reactive, vat, and azo dyes with better fastness properties as compared to that of cotton.

- It can also be dyed with basic dyes at room temperature due to the presence of lignin and hemicellulose, which are more than 15% amorphous in character with acidic nature.

- The pineapple fibers can be used in wide applications from apparel to technical textiles.

- Used in industrial applications like tires and conveyor belts and can be used in the paper manufacturing industry.

- The pineapple fabric used to make upholstery and furnishing.

- It is used for making table linens, bags, mats, and other clothing items.

- It is used for making a thin and transparent embroidered garment known as barong Tagalog which has worn over a shirt and other formal wear in the Philippines.

- It is used for making wedding attire for men, blouses for women, kimonos, panuelos, gowns, and handkerchiefs.

- Sports items, baggage, automobiles, cabinets, and mats. Surface modified PALF is introduced for making machinery parts like belt cord, conveyor belt cord, transmission cloth, and air-bag tying cords.

- It is generally used in making threads for textile fabrics.

- It can be suitable for various other applications such as cosmetics, medicine, and biopolymers coating for chemicals.

- It is used to reinforce the corrugated roofing sheets.

Description

Properties of pineapple fiber:

length(mm): 10-90

Fineness(tex) : 2.44-3.56

Fiber Tenacity (gm/tex) : 30.00-51.00

Elongation %: 2.5-3.5

Moisture regain % : 11.5-12.00

Water swelling % : 48.96

True density gms/cc : 1.5260

Porosity % : 9.00

Flexural rigidity dyne/cm2 : 3.80

Torsional rigidity dyne/cm2 X1010 : 0.36

L/B ratio : 450

Moisture content : 11.8 % max

Tensile strength (MPa) : 413–1627

Young’s modulus (GPa) : 34.5–82.51

Specific strength (GPa/g/cm3) : 0.3–1.1

Specific modulus (GPa/g/cm3) : 22.7–54.3

Initial modulus(cN/tex): 570-700

Elongation at break (%) : 1.6 -3

Dia.(mm) : 20–80

Microfibril angle : 8-14

It has high insulation power and high absorbency.

The thermal conductivity of this fiber is below at 0.0273 watts/m2/k which suggests that these fibers can be used as good thermal insulators.

It has high flexural and torsional rigidity than that of cotton fiber.

It has a high degree of crystallinity with a spiral angle of 15 C

Effect of alkali: when it is treated with 18% NaOH results in length shrinkage and enhances breaking elongation.

Effect of H2O2: H2O2 improves its fineness up to 5 to 6% but reduces tensile strength by 40 to 45%.

Pineapple fiber dissolves in 60% sulphuric acid in 5 min.

Reviews

There are no reviews yet.